The issues of hot-spots type in the railway disc brake

1

Politechnika Poznańska

2

DB Systemtechnik GmbH

Online publication date: 2021-02-02

Publication date: 2021-02-03

Rail Vehicles/Pojazdy Szynowe 2021,1,33-43

KEYWORDS

ABSTRACT

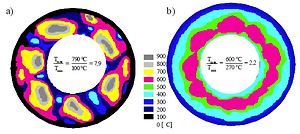

The article deals with the issues of hot areas occurring in friction disc brakesbased on the literature review. The results of stand tests of the railway disc brake in aspect of identifying the hot areas of hot-spots are presented. In addition, the test methodology with the use of a thermovision camera for observation and registration of hot areas is developed for the stand tests.Thermovision images from the various braking speeds, where there are hot-spots, are presented for the friction pair of cast-iron brake disc and organic friction lining according to the requirements of UIC 541-3 leaflet. A model to determine the number of macroscopic hot areas on the surface of the brake disc is developed on this basis.The model is verified for braking with a greater emphasis regarding the fundamental tests.

REFERENCES (21)

1.

Abbasi S., Teimourimanesh S., Vernersson T., Sellgren U., Olofsson U., Lundén R.: Temperature and thermoelastic instability at tread braking using cast iron friction material. Wear, 2014, 314, s. 171-180.

2.

Aranganathan N., Jayashree B.: Development of copper-free eco-friendly brake-friction material using novel ingredients. Wear, 2016, 352-353, s. 79-91.

3.

Belhocine A., Bouchetara M.: Thermomechanical modelling of dry contacts in automotive disc brake. International Journal of Thermal Sciences, 2012, 60, s. 161-170.

4.

Grzes P., Oliferuk W., Adamowicz A., Kochanowski K., Wasilewski P., Yevtushenko A.A.: The numerical-experimental scheme for the analysis of temperature field in a pad-disc braking system of a railway vehicle at single braking. International Communications in Heat and Mass Transfer, 2016, 75, s. 1-6.

5.

Kasem H., Brunel J.F., Dufrénoy P., Siroux M., Desmet B.: Thermal levels and subsurface damage induced by the occurrence of hot spots during high-energy braking. Wear, 2011, 270, s. 355-364.

6.

Kodeks UIC 541-3. Hamulec–Hamulec tarczowy i jego zastosowanie. Warunki dopuszczenia okładzin hamulcowych. Wydanie 7, czerwiec 2010.

7.

Kumar M., Boidin X., Desplanques Y., Bijwe J.: Influence of various metallic fillers in friction materials on hot-spot appearance during stop braking. Wear, 2011, 270, s. 371-381.

8.

Li Z., Han J., Yang Z., Li W.: Analyzing the mechanisms of thermal fatigue and phase change of steel used in brake discs. Engineering Failure Analysis, 2015, 57, s. 202-218.

9.

Mackin T.J., Noe S.C., Ball K.J., Bedell B.C., Bim-Merle D.P. i in.: Thermal cracking in disc brakes. Engineering Failure Analysis, 2002, 9, s. 63-76.

10.

Oder G., Reibenschuh M., Lerhe T., Šraml M., Šamec B., Potrč I.: Thermal and stress analysis of brake discs in railway vehicles. Advanced Engineering, 2009, 3, s. 95-102.

11.

Panier S., Dufrénoy P., Weichert D.: An experimental investigation of hot spots in railway disc brakes. Wear, 2004, 256, s. 764-773.

12.

Reibenschuh M., Oder G., ? u? F., Potrč I.: Modelling and Analysis of Thermal and Stress Loads in Train Disc Brakes – Braking from 250km/h to Standstill. Journal of Mechanical Engineering 2009, 55, 7-8, s. 494-502.

13.

Sawczuk W., Kowalczyk J., Ulbrich D.: Zastosowanie kamery termowizyjnej w badaniach nieniszczących wybranych elementów kolejowego układu hamulcowego. Przegląd Spawalnictwa 2017, 89(4), s. 19-21.

14.

Sawczuk W., Tomaszewski F.: Ocena rozkładu średniej temperatury pary ciernej tarcza hamulcowa–okładzina wraz z obsadą hamulcową w czasie hamowania ze stałą mocą. Pomiary Automatyka Kontrola PAK, 2013, 59(9), s. 938-941.

15.

Trzmielowski S., Urbańczyk P.: Badania układów hamulcowych pojazdów szynowych w zakresie odporności na obciążenie cieplne. Czasopismo Techniczne Mechanika, 2011, z. 4.

16.

Wirth X.: Improving the performance of disc brakes on high-speed rail vehicles with a novel types of brake pad: Isobar. RTR, 1998, 1, s. 24-29.

17.

Wu S.C., Zhang S.Q., Xu Z.W.: Thermal crack growth-based fatigue life prediction due to braking for a high-speed railway brake disc. International Journal of Fatigue, 2016, 87, s. 359-369.

18.

Wu S.C., Xu Z.W., Yu C., Kafka O.L., Liu W.K.: A physically short fatigue crack growth approach based on low cycle fatigue properties. International Journal of Fatigue, 2017, 103, s. 185-195.

19.

Yan H.B., Zhang Q.C., Lu T.J.: Heat transfer enhancement by X-type lattice in ventilated brake disc. International Journal of Thermal Sciences, 2016, 107, s. 39-55.

20.

Zagrodzki P., Truncone S.A.: Generation of hot spots in a wet multidisc clutch during short-term engagement. Wear, 2003, 254, s. 474-491.

21.

Zagrodzki P.: Analysis of thermomechanical phenomena in multidisc clutches and brakes, Wear, 1990, 140, 2, s. 291-308.

CITATIONS (4):

1.

Testing the wear of wheelsets of EN97 series vehicles in terms of geometrical parameters of the wheel profile in two-year operation

Wojciech Sawczuk, Armando Miguel Rilo Cañás, Sławomir Kołodziejski

Rail Vehicles/Pojazdy Szynowe

Wojciech Sawczuk, Armando Miguel Rilo Cañás, Sławomir Kołodziejski

Rail Vehicles/Pojazdy Szynowe

2.

Thermal imaging of the disc brake and drive train in an electric locomotive in field conditions

Wojciech Sawczuk, Armando Miguel Rilo Cañás, Sławomir Kołodziejski

Combustion Engines

Wojciech Sawczuk, Armando Miguel Rilo Cañás, Sławomir Kołodziejski

Combustion Engines

3.

Evaluation of weight wear of disc brake pads after test stands

Wojciech Sawczuk, Armando Rilo Cañás, Sławomir Kołodziejski

Rail Vehicles/Pojazdy Szynowe

Wojciech Sawczuk, Armando Rilo Cañás, Sławomir Kołodziejski

Rail Vehicles/Pojazdy Szynowe

4.

Model of energy consumption by brake discs of rail vehicles

Wojciech Sawczuk, Mateusz Jüngst, Daniel Kaczmarek

Rail Vehicles/Pojazdy Szynowe

Wojciech Sawczuk, Mateusz Jüngst, Daniel Kaczmarek

Rail Vehicles/Pojazdy Szynowe

Share

RELATED ARTICLE

We process personal data collected when visiting the website. The function of obtaining information about users and their behavior is carried out by voluntarily entered information in forms and saving cookies in end devices. Data, including cookies, are used to provide services, improve the user experience and to analyze the traffic in accordance with the Privacy policy. Data are also collected and processed by Google Analytics tool (more).

You can change cookies settings in your browser. Restricted use of cookies in the browser configuration may affect some functionalities of the website.

You can change cookies settings in your browser. Restricted use of cookies in the browser configuration may affect some functionalities of the website.