PRACA ORYGINALNA

Concept for an innovative screw coupling system production process

1

Ebrima sp. z o.o., Polska

2

Poznań University of Technology, Department of Railway Transport, Polska

Data nadesłania: 21-12-2023

Data ostatniej rewizji: 23-04-2024

Data akceptacji: 28-04-2024

Data publikacji online: 04-05-2024

Data publikacji: 16-11-2024

Autor do korespondencji

Rail Vehicles/Pojazdy Szynowe 2024,1-2,30-38

SŁOWA KLUCZOWE

DZIEDZINY

STRESZCZENIE

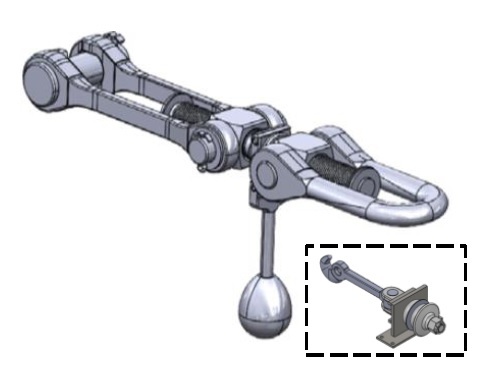

The article presents the concept of an innovative approach to the production of a screw coupling system, a key element in rail vehicles. The use of ready-made components from various subsuppliers, combined with new quality control methods, offers an opportunity for a significant reduction in cost and production time while increasing the efficiency and flexibility of the process. Key stages of the production process are highlighted, from the selection of semifinished products, through quality control, to the final assembly and validation. The applied strategies can minimise waste, increase material efficiency, and have a positive impact on the environment. This study constitutes a significant contribution to the development of sustainable production in the railway industry, with an emphasis on organisational, process, and product innovations.

REFERENCJE (16)

1.

Batson RG. Supplier management in service industry: What can be learned from automotive manufacturing? In Moynihan GP (ed): Contemporary issues and research in operations management. IntechOpen. 2018. https://doi.org/10.5772/intech....

2.

Commission Implementing Regulation (EU) No 402/2013 of 30 April 2013 on the common safety method for risk evaluation and assessment and repealing Regulation (EC) No 352/2009. http://data.europa.eu/eli/reg_....

3.

Condé GCP, Oprime PC, Pimenta ML, Sordan JE, Bueno CR. Defect reduction using DMAIC and Lean Six Sigma: a case study in a manufacturing car parts supplier. Int J Qual Reliabil Manage. 2023;40(9):2184-2204. https://doi.org/10.1108/IJQRM-....

4.

de Kemmeret F. Is automatic coupling on freight wagon will become reality? https://mediarail.wordpress.co... (accessed on 20.12.2023).

5.

Dewulf W, Duflou J, Ander Å. Toward a sectorwide design for environment support system for the rail industry. Environ Manage. 2004;34(2):181-190. https://doi.org/10.1007/s00267....

6.

Eggers JE, Hofman E, Schiele H, Holschbach E. Identifying the ‘right’ supplier for module developments — a cross-industrial case analysis. Int J Innov Manage. 2017;21(3):1-33. https://doi.org/10.1142/S13639....

7.

Ma P, Meng Y, Gong Y, Li M. Optimal models for sustainable supply chain finance: evidence from electric vehicle industry. Int J Prod Res. 2023;61(15):5075-5093. https://doi.org/10.1080/002075....

8.

Muruganandham R, Sakthirama V, Basha MR, Abuthakeer AS, Sivakumar SD. Supplier selection in a manufacturing industry using AHP, fuzzy and neural network: a study using multi criteria decision making methods. J Adv Res Dynam Cont Syst. 2020;12(05):489-497. https://doi.org/10.5373/JARDCS....

9.

Muvunzi R, Mpofu K, Daniyan I, Fameso F. Analysis of potential materials for local production of a rail car component using additive manufacturing. Heliyon. 2022;8(5):e09405. https://doi.org/10.1016/j.heli....

10.

Pereseina V, Jensen L-M, Hertz S, Cui L. Challenges and conflicts in sustainable supply chain management: evidence from the heavy vehicle industry. Supply Chain Forum: An International Journal. 2014;15(1):22-32. https://doi.org/10.1080/162583....

12.

Qureshi SA, Naseem A, Ahmad Y. Outsourcing or in-house manufacturing in Hi-tech industry: supply chain process with Delphi-AHP approach. Kybernetes. 2023. https://doi.org/10.1108/K-08-2....

13.

Rashid FAA, Hishamuddin H, Saibani N, Abu Mansor MR, Harun Z. A review of supply chain uncertainty management in the end-of-life vehicle industry. Sustainability. 2022;14(19):12573. https://doi.org/10.3390/su1419....

14.

Samson KK. Outsourcing vs. in-house production: a strategic decision to increase a firm’s product innovation and internationalization. Economics of Innovation eJournal 2019.

15.

Strange R, Magnani G. The performance consequences of manufacturing outsourcing: review and recommendations for future research. Breaking up the Global Value Chain (Advances in International Management). 2017;30:217-244. https://doi.org/10.1108/S1571-....

16.

Temponi C, Lambert T. Managing outsourcing in a joint development environment: impact on innovation and new product development process. IEMC’01 Proceedings. Change Management and the New Industrial Revolution. IEMC-2001. 2001:335-340. https://doi.org/10.1109/IEMC.2....

Udostępnij

Przetwarzamy dane osobowe zbierane podczas odwiedzania serwisu. Realizacja funkcji pozyskiwania informacji o użytkownikach i ich zachowaniu odbywa się poprzez dobrowolnie wprowadzone w formularzach informacje oraz zapisywanie w urządzeniach końcowych plików cookies (tzw. ciasteczka). Dane, w tym pliki cookies, wykorzystywane są w celu realizacji usług, zapewnienia wygodnego korzystania ze strony oraz w celu monitorowania ruchu zgodnie z Polityką prywatności. Dane są także zbierane i przetwarzane przez narzędzie Google Analytics (więcej).

Możesz zmienić ustawienia cookies w swojej przeglądarce. Ograniczenie stosowania plików cookies w konfiguracji przeglądarki może wpłynąć na niektóre funkcjonalności dostępne na stronie.

Możesz zmienić ustawienia cookies w swojej przeglądarce. Ograniczenie stosowania plików cookies w konfiguracji przeglądarki może wpłynąć na niektóre funkcjonalności dostępne na stronie.