PRACA ORYGINALNA

Model of energy consumption by brake discs of rail vehicles

1

Institute of Transport, Poznan University of Technology, Polska

2

Faculty of Civil and Transport Engineering, Institute of Transport, Polska

3

ATC, Grupa, Polska

Data nadesłania: 20-02-2024

Data ostatniej rewizji: 25-03-2024

Data akceptacji: 09-04-2024

Data publikacji online: 15-04-2024

Data publikacji: 16-11-2024

Autor do korespondencji

Wojciech Sawczuk

Institute of Transport, Poznan University of Technology, Piotrowo 3, 60-965, Poznań, Polska

Institute of Transport, Poznan University of Technology, Piotrowo 3, 60-965, Poznań, Polska

Rail Vehicles/Pojazdy Szynowe 2024,1-2,11-20

SŁOWA KLUCZOWE

DZIEDZINY

STRESZCZENIE

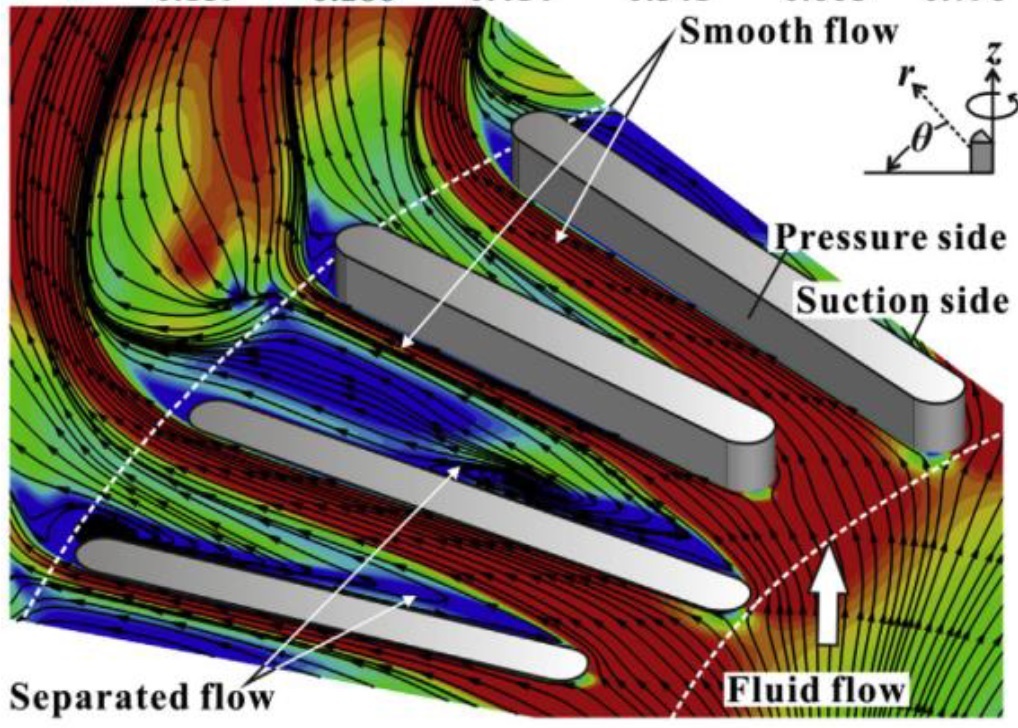

The aim of the article is to present a computational model to determine the losses generated by the brake discs of rail vehicles. The energy consumption of the disc (energy losses) is divided into inertia losses and fan losses. The article is preceded by a review of the design solutions of brake discs of rail vehicles in terms of their ventilation and cooling after braking. Particular attention was paid to three types of brake disc designs with ventilation blades, bars and other shapes of ventilation bridges, and how the ventilation of these discs affects energy losses. On the one hand, forced ventilation of brake discs shortens the cooling time after intensive braking, on the other hand, it causes energy losses due to forced ventilation when the brakes are not used. The article presents the state of knowledge regarding the cooling efficiency of brake discs as a result of forced ventilation and presents a method for calculating the energy consumption generated by the brake disc in relation to the rotational speed. The energy losses were divided in the article into inertia losses due to the rotating mass and losses on the fan, in which the energy necessary for the rotation of the brake disc was determined from the method of calculating centrifugal fans with known geometric dimensions.

REFERENCJE (45)

1.

Anoop S, Natarajan S, Kumaresh Babu SP. Analysis of factors influencing dry sliding wear behavior of Al/SiCp–brake pad tribosystem. Materials and Design. 2009;30:3831-3838. https://doi.org/10.1016/j.matd....

2.

Bajerlein M, Czerwiński J, Merkisz J, Daszkiewicz P, Rymaniak Ł. Wysokotemperaturowa stal stopowa wykorzystywana w pojazdach kolejowych (in Polish). TTS Technika Transportu Szynowego. 2017;24(12):228-232.

3.

Bartłomiejczyk M. Rekuperacja energii hamowania w praskim systemie tramwajowym (in Polish). TTS Technika Transportu Szynowego. 2015;1-2:50-53.

4.

Bieniek A, Graba M, Mamala J, Prażnowski K, Hennek K. Energy consumption of a passenger car with a hybrid powertrain in real traffic conditions. Combustion Engines. 2022;191(4):15-22. https://doi.org/10.19206/CE-14....

5.

Cieślik W, Szwajca F, Golimowski J. The possibility of energy consumption reduction using the ECO driving mode based on the RDC test. Combustion Engines. 2020;182(3): 59-69. https://doi.org/10.19206/CE-20....

6.

Daszkiewicz P, Kołodziejek D. Comparison and analysis of modern combustion powertrain systems of rail vehicles. Combustion Engines. 2024;196(1):46-53. https://doi.org/10.19206/CE-17....

7.

Durzyński Z. Hydrogen-powered drives of the rail vehicles (part 1). Rail Vehicles/Pojazdy Szynowe. 2021;2:29-40. https://doi.org/10.53502/RAIL-....

8.

Durzyński Z. Hydrogen-powered drives of the rail vehicles (part 2). Rail Vehicles/Pojazdy Szynowe. 2021;3:1-11. https://doi.org/10.53502/RAIL-....

10.

Elzayady N, Elsoeudy R. Microstructure and wear mechanisms investigation on the brake pad. J Mater Process Tech. 2021;11:2314-2335. https://doi.org/10.1016/j.jmrt....

11.

Energy and the Green Deal, Clean Energy Transition: https://commission.europa.eu/s... (accessed on 14.02.2024).

12.

Far M, Gallas D, Urbański P, Woch A, Mieżowiec K. Modern combustion-electric PowerPack drive system design solutions for a hybrid two-unit rail vehicle. Combustion Engines. 2022;190(3):80-87. https://doi.org/10.19206/CE-14....

13.

Idris UD, Aigbodion VS, Akubakar IJ, Nwoye CI. Ecofriendly asbestos free brake-pad: using banana peels. Journal of King Saud University – Engineering Sciences. 2015;27:185-192. https://doi.org/10.1016/j.jksu....

14.

Park J, Joo B, Seo H, Song W, Lee JJ, Lee WK, Jang H. Analysis of wear induced particle emissions from brake pads during the worldwide harmonized light vehicles test procedure (WLTP). Wear. 2021;466-467:203539. https://doi.org/10.1016/j.wear....

16.

Maciołek T, Drążek Z. Zasobnik energii w tramwaju zmniejszający zużycie energii (in Polish). TTS Technika Transportu Szynowego. 2004;10:54-57.

17.

Mahale V, Bijwe J. Exploration of plasma treated stainless steel swarf to reduce the wear of copper-free brake-pads. Tribol Int. 2020;144:106111. https://doi.org/10.1016/j.trib....

18.

Mamala J, Śmieja M, Prażnowski K. Analysis of the total unit energy consumption of a car with a hybrid drive system in real operating conditions. Energies. 2021;14(13):3966. https://doi.org/10.3390/en1413....

19.

Matej J, Orliński P. Reducing wheel wear of a motorised metro car on a curved track with a small curve radius. Rail Vehicles/Pojazdy Szynowe. 2023;3-4:25-32. https://doi.org/10.53502/RAIL-....

20.

Nishimura T. efWING−New-Generation Railway Bogie. Japanese Railway Engineering. 2016;194:13-14.

21.

Nishimura T, Taga Y, Ono T, Konoike F, Tsumura Y, Inamura F et al. efWING–New-Generation Railway Bogie. Kawasaki Technical Review. 2016;177:27-32.

22.

Pielecha I, Cieślik W, Borowski P, Czajka J, Bueschke W. The development of combustion engines for hybrid drive systems. Combustion Engines. 2014;158(3):23-35. https://doi.org/10.19206/CE-11....

23.

Pielecha I, Engelmann D, Czerwiński J, Merkisz J. Use of hydrogen fuel in drive systems of rail vehicles. Rail Vehicles/Pojazdy Szynowe. 2022;1-2:10-19. https://doi.org/10.53502/RAIL-....

24.

Regulski P. Assessment of the life cycle of city buses with diesel and electric drive in the operation phase. Combustion Engines. 2023;193(2):117-121. https://doi.org/10.19206/CE-16....

25.

Sawczuk W, Rilo Cañás AM. The issues of hot-spots type in the railway disc brake. Rail Vehicles/Pojazdy Szynowe. 2021,1:33-43. https://doi.org/10.53502/RAIL-....

26.

Sawczuk W, Rilo Cañás AM, Kołodziejski S. Evaluation of weight wear of disc brake pads after test stands. Rail Vehicles/Pojazdy Szynowe. 2022;3-4:53-59. https://doi.org/10.53502/RAIL-....

27.

Sawczuk W, Jüngst M. Tarcze hamulcowe pojazdów szynowych (in Polish). TTS Technika Transportu Szynowego. 2016;12:496-502.

28.

Sawczuk W. Selected issues of operational use of rail disc brake. The Archives of Automotive Engineering. 2011;53(3):41-52. https://doi.org/10.5604/123475....

29.

SIEMENS G. Auslegung und Leistungsgrenzen von Scheibenbremsen. ZEV-Glas. Ann. 1988;112(4):139-143.

31.

Skuza A, Szumska E, Jurecki R. Fuel consumption and CO2 emission analysis of hybrid and conventional vehicles in urban driving conditions. Combustion Engines. 2023;195(4):48-55. https://doi.org/10.19206/CE-16....

32.

Słowiński M. An Analysis of CFRP application in the construction of rail vehicles. Problemy Kolejnictwa. 2021;193:105-103. https://doi.org/10.36137/1935E.

33.

Sorochtej M. Kształtowanie jakości zespołu ciernego hamulca tarczowego. Przegląd Kolejowy. 1991;1:15-21.

34.

Szumska E, Jurecki R. Technological developments in vehicles with electric drive. Combustion Engines. 2023;194(3):38-47. https://doi.org/10.19206/CE-16....

35.

Śmietana K. Euro 7, czyli wątpliwości wokół norm emisji zanieczyszczeń (in Polish). DGP Dziennik Gazeta Prawna. 2023;2(3). https://serwisy.gazetaprawna.p....

36.

Tirović M. Energy thrift and improved performance achieved through novel railway brake discs. Appl Energ. 2009;86:317-324. https://doi.org/10.1016/j.apen....

37.

Urbaniak M, Kardas-Cinal E. Optimization of using recuperative braking energy on a double-track railway line. Transp Res Proc. 2019;40:1208-1215. https://doi.org/10.1016/j.trpr....

38.

Walczak J. Promieniowe sprężarki dmuchawy i wentylatory. Wydawnictwo Politechniki Poznańskiej. Poznan 2013.

39.

Wirth X. Improving the performance of disc brakes on high-speed rail vehicles with a novel types of brake pad: isobar. RTR. 1998;1:24-29.

40.

Wirth X. Disc brakes to stop the world's fastest trains. Railway Gazette February. 1986.

41.

Wu SC, Zhang SQ, Xu ZW. Thermal crack growth-based fatigue life prediction due to braking for a high-speed railway brake disc. Int J Fatigue. 2016;87:359-369. https://doi.org/10.1016/j.ijfa....

42.

Varazhun I, Shimanovsky A, Zavarotny A. determination of longitudinal forces in the cars automatic couplers as train electrodynamic braking. Procedia Engineer. 2016;134:415-421. https://doi.org/10.1016/j.proe....

43.

Yan HB, Feng SS, Yang XH, Lu TJ. Role of cross-drilled holes in enhanced cooling of ventilated brake discs. Appl Therm Eng. 2015;91:318-333. https://doi.org/10.1016/j.appl....

44.

Yan HB, Zhang QC, Lu TJ. Heat transfer enhancement by X-type lattice in ventilated brake disc. Int J Therm Sci. 2016;107:39-55. https://doi.org/10.1016/j.ijth....

45.

Zaitong International Trading Co. Ltd. https://www.zhonganzt.com/pl/t... (accessed on 14.02.2024).

CYTOWANIA (1):

1.

Emission testing of diesel multiple units complying with different emission standards during real operating conditions

Łukasz Rymaniak, Jakub Sobczak, Natalia Szymlet, Piotr Pielecha, Sławomir Wiśniewski

Rail Vehicles/Pojazdy Szynowe

Łukasz Rymaniak, Jakub Sobczak, Natalia Szymlet, Piotr Pielecha, Sławomir Wiśniewski

Rail Vehicles/Pojazdy Szynowe

Przetwarzamy dane osobowe zbierane podczas odwiedzania serwisu. Realizacja funkcji pozyskiwania informacji o użytkownikach i ich zachowaniu odbywa się poprzez dobrowolnie wprowadzone w formularzach informacje oraz zapisywanie w urządzeniach końcowych plików cookies (tzw. ciasteczka). Dane, w tym pliki cookies, wykorzystywane są w celu realizacji usług, zapewnienia wygodnego korzystania ze strony oraz w celu monitorowania ruchu zgodnie z Polityką prywatności. Dane są także zbierane i przetwarzane przez narzędzie Google Analytics (więcej).

Możesz zmienić ustawienia cookies w swojej przeglądarce. Ograniczenie stosowania plików cookies w konfiguracji przeglądarki może wpłynąć na niektóre funkcjonalności dostępne na stronie.

Możesz zmienić ustawienia cookies w swojej przeglądarce. Ograniczenie stosowania plików cookies w konfiguracji przeglądarki może wpłynąć na niektóre funkcjonalności dostępne na stronie.